Thunder Light Shipments

packages under 150 lb., and LTL shipments

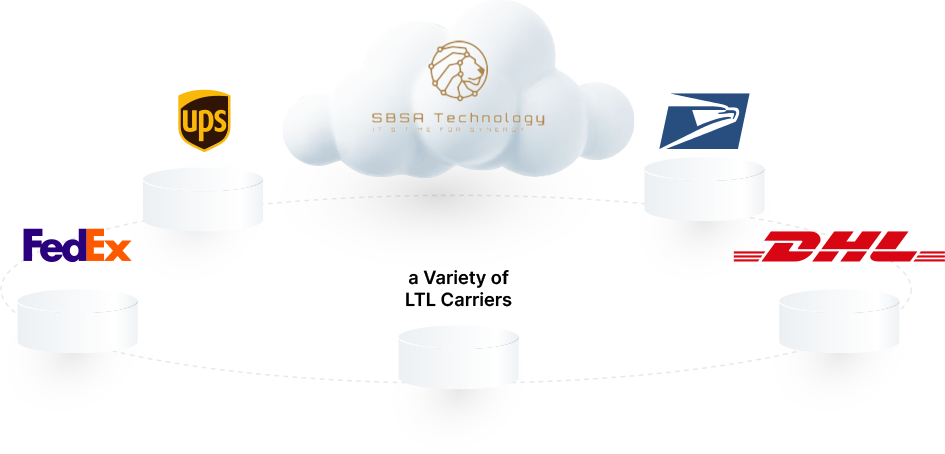

Connectivity to Shipping Partners

Tracking Information

You will never have to type another shipping or customer address again. The module provides a powerful logistics tool that communicates with a variety of carriers, generates carrier labels, BOL, and packing slips. Afterwards, it records the tracking information and sends it back to your partners. We make sure that the tracking information is easy to access for any customer service assistant. This process is fully automated.

Dynamic Warehouse Selection

Additionally, businesses with multiple warehouse locations can perform an efficient dynamic warehouse selection based on the availability of inventory and the closest shipping warehouse to the customer. This feature reduces the shipping time and cost to ship a product. The software automatically checks, which warehouses have the product, calculates their distance to the customer, selects the closest facility, and sends the order for processing.

_EasiestAdmin_Mid-Market_EaseOfAdmin.svg)

_UsersMostLikelyToRecommend_Nps.svg)

_MostImplementable_Mid-Market_Total.svg)

_MomentumLeader_Leader.svg)

_HighPerformer_Mid-Market_AsiaPacific_HighPerformer.svg)

_HighPerformer_AsiaPacific_HighPerformer.svg)

_HighPerformer_Asia_HighPerformer.svg)

_EasiestToUse_Mid-Market_EaseOfUse.svg)

_EasiestToUse_EaseOfUse.svg)

_EasiestToDoBusinessWith_Small-Business_EaseOfDoingBusinessWith.svg)

_EasiestToDoBusinessWith_Mid-Market_EaseOfDoingBusinessWith.svg)

_EasiestToDoBusinessWith_EaseOfDoingBusinessWith.svg)

_EasiestSetup_Small-Business_EaseOfSetup.svg)

_EasiestSetup_Mid-Market_EaseOfSetup.svg)